views

Plastic injection molding is one of the most commonly used manufacturing processes in the production of plastic parts. From automotive components to consumer goods, the versatility and efficiency of this process make it indispensable for mass production. However, choosing the right plastic injection molding service provider is crucial, especially for large-scale production. Selecting a partner who can meet your specific needs, deliver high-quality results, and provide consistent service is essential for your business's success. This article will explore the key factors to consider when choosing plastic injection molding services for large-scale production.

Experience and Expertise of the Plastic Injection Molding Service Provider

When selecting a plastic injection molding service provider, the first thing to consider is their level of experience and expertise in the industry. A company with years of experience is more likely to understand the intricacies of large-scale production and can navigate the complexities involved in the process. With the rapid technological advancements in manufacturing, experienced companies will also be able to utilize the latest machinery and techniques to provide efficient solutions.

Moreover, the expertise of the provider should align with your specific production needs. For large-scale production, it’s essential that the company has the capacity to handle high-volume runs while maintaining product quality. A provider with the right experience will understand the importance of precision, cost-efficiency, and consistency, ensuring your project is completed on time and within budget.

Quality Assurance and Compliance Standards

For large-scale production, the quality of your products is non-negotiable. It is crucial that the plastic injection molding service you choose adheres to strict quality assurance (QA) standards and regulatory compliance. The service provider should implement robust quality control systems throughout the production process to ensure that each part meets the required specifications and tolerances.

Additionally, the provider should comply with industry standards, such as ISO certifications, that indicate their commitment to producing high-quality products. For some industries, such as medical devices or automotive parts, compliance with regulatory bodies like the FDA or IATF 16949 (for automotive quality management) may be necessary. This guarantees that the service provider not only delivers high-quality products but also meets any legal or industry-specific requirements.

Production Capabilities and Equipment

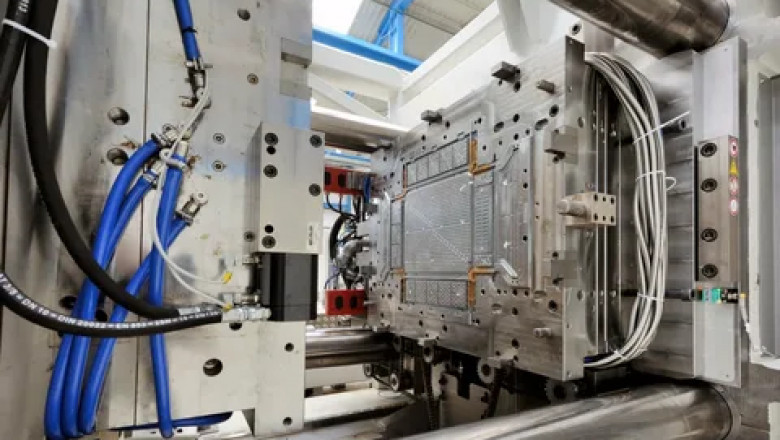

The scale of your production needs will directly influence the type of plastic injection molding service provider you choose. Large-scale production requires the ability to manage high volumes, maintain speed, and deliver efficiency without compromising quality. A reliable plastic injection molding provider should have state-of-the-art machinery capable of handling high-speed and high-volume production runs.

The choice of equipment is critical for ensuring that production runs smoothly and consistently. Advanced equipment such as multi-cavity molds, automation tools, and quick-change systems can significantly improve cycle times, reduce downtime, and enhance the overall productivity of the molding process. Additionally, it’s essential to work with a provider who can scale their operations to meet the demands of your project as it grows, ensuring that they can accommodate potential increases in production volume.

Customization and Material Options

Plastic injection molding allows for the use of a wide variety of materials, from standard thermoplastics to specialized composites and thermosets. When selecting a plastic injection molding service provider, it is crucial to consider the range of material options they offer. The right material will depend on the specific requirements of your product, such as durability, heat resistance, and flexibility.

A reputable plastic injection molding service provider should offer customization options that align with your specific design and performance needs. They should be able to guide you in selecting the most suitable material for your application while ensuring the quality and functionality of the final product. Additionally, if your production requires complex designs or unique features, the provider should have the expertise to create custom molds that meet your specifications and can deliver the desired results efficiently.

Cost-Effectiveness and Lead Time

While cost should not be the only deciding factor in choosing a plastic injection molding service, it is certainly an important one. For large-scale production, the overall cost of manufacturing can significantly impact your profit margins. A reliable service provider should offer transparent pricing, providing a breakdown of costs related to materials, labor, tooling, and any additional services.

In addition to cost, lead time is a critical consideration. The faster you can get your products to market, the better. Choose a plastic injection molding service provider who can meet your production deadlines and offer quick turnaround times without sacrificing quality. It’s also helpful if the provider can offer flexibility in lead times, accommodating urgent or unexpected changes in production schedules, which is often crucial for large-scale production runs.

Conclusion

Choosing the right plastic injection molding services for large-scale production is a crucial decision that can significantly impact the quality, cost, and efficiency of your manufacturing process. By focusing on key factors such as the provider’s experience, quality assurance systems, production capabilities, material options, and cost-effectiveness, you can ensure that your project will be executed successfully. Taking the time to evaluate and select the right partner will ultimately lead to a smoother production process, high-quality products, and a more cost-effective solution for your business.

Comments

0 comment