views

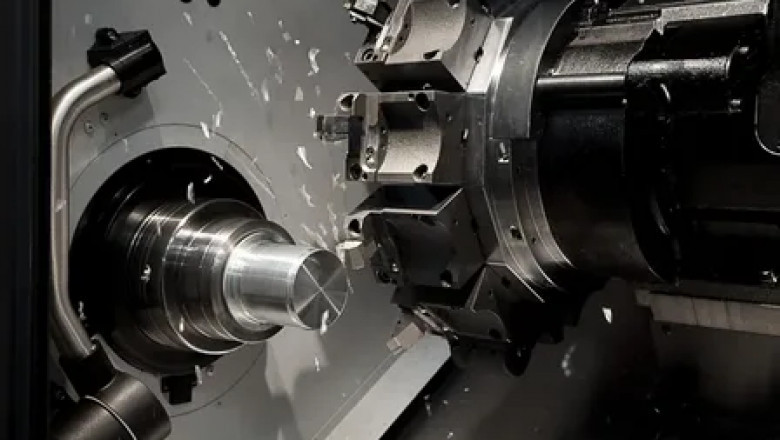

CNC (Computer Numerical Control) machining has revolutionized manufacturing by delivering unparalleled precision, repeatability, and efficiency. Whether you're developing prototypes, creating custom parts, or mass-producing components, choosing the right CNC machining techniques is crucial for achieving optimal results. With a variety of CNC processes available—including milling, turning, grinding, and more—selecting the best fit requires a clear understanding of project requirements, material properties, tolerances, and production volume. This article outlines the key considerations and best practices to help you choose the most suitable CNC machining techniques for your specific project.

From understanding the basics to evaluating complex technical aspects, making the right decisions about CNC machining techniques can drastically improve product quality, reduce costs, and shorten production timelines. By aligning machining capabilities with project needs, engineers and designers can overcome manufacturing challenges and achieve functional and economic success. Let’s explore how to choose the right CNC machining techniques through detailed insights into five essential aspects of the process.

Understand Your Project Requirements and Specifications

The first and most critical step in selecting the right CNC machining techniques is defining your project requirements in detail. This includes the purpose of the part, the desired surface finish, dimensional tolerances, and functional characteristics. Are you building a structural component that requires strength and durability, or a precision optical piece with extremely tight tolerances? Understanding these parameters helps narrow down the list of compatible CNC processes. For instance, tight tolerance parts may benefit from techniques like CNC grinding, while general structural parts could be milled or turned efficiently.

Equally important is determining the intended use and lifecycle of the component. For example, prototyping may allow for slightly looser tolerances and faster turnaround, whereas aerospace or medical parts demand extremely high precision and quality control. The type of industry you're working in will also influence your technique selection. Aerospace, automotive, and medical industries often have stringent compliance standards that only specific CNC machining techniques can satisfy. By clearly documenting all the technical and performance requirements, you set the foundation for selecting the most appropriate machining approach.

Evaluate the Material Properties of Your Component

The material you choose plays a vital role in determining the CNC machining techniques best suited for your project. Different materials have unique characteristics that influence how they can be machined. For example, aluminum is lightweight and relatively easy to machine, making it suitable for high-speed CNC milling. On the other hand, harder materials like stainless steel or titanium require more robust techniques and specialized tooling, often involving slower speeds and higher cutting forces. Certain plastics may be better suited for CNC routing rather than milling or turning due to their flexibility and low melting points.

In addition to machinability, the material’s reaction to heat, stress, and vibration can also impact your technique selection. Some materials produce significant heat during machining and may warp or lose tolerance if not handled correctly. Choosing the right CNC machining techniques means selecting methods that work efficiently with your material without compromising quality. For example, using coolant systems, high-speed spindles, or even multi-axis machining may be necessary for certain alloys. A thorough understanding of how your chosen material behaves under CNC conditions will ensure better results and longer tool life.

Match the CNC Technique to Part Geometry and Design Complexity

Not all CNC machining techniques are created equal when it comes to handling complex geometries. Some parts require intricate cuts, undercuts, or multi-angle surfaces that cannot be achieved using basic milling or turning. In such cases, advanced techniques such as 5-axis CNC machining or electrical discharge machining (EDM) may be necessary. For example, if your design includes curved surfaces and deep cavities, 5-axis CNC machining provides the flexibility to approach the workpiece from multiple angles without repositioning, resulting in more accurate and efficient machining.

Conversely, simpler parts with uniform shapes and fewer features may only require 3-axis CNC milling or standard turning, which are faster and more cost-effective. Understanding your part's geometry will help you decide if investing in advanced capabilities is justified. Additionally, software compatibility plays a role—complex parts often require sophisticated CAD/CAM programming to ensure accurate tool paths and collision avoidance. Choosing the right CNC machining techniques based on geometry ensures that your design intentions are preserved during manufacturing, without sacrificing time or budget.

Consider Production Volume and Cost Efficiency

The scale of production is another key factor when selecting CNC machining techniques. For one-off prototypes or low-volume batches, flexibility and rapid setup are often more important than cycle time. Techniques like 3D CNC milling or hybrid machining, which allow quick adjustments and tool changes, are ideal in these scenarios. These approaches can accommodate evolving design needs while keeping costs relatively low due to minimal setup requirements. In contrast, high-volume production demands repeatability, automation, and speed—making it essential to choose techniques that can be scaled efficiently.

In such high-output settings, automated tool changers, pallet changers, and even lights-out manufacturing with robotic loading systems can dramatically reduce per-unit costs. Techniques like Swiss turning or multi-spindle CNC machines are often used for producing large quantities of precision components at scale. Selecting the right CNC machining techniques also involves evaluating total cost of ownership—including tool wear, maintenance, energy consumption, and operator requirements. Balancing upfront investment with long-term efficiency ensures that your machining strategy aligns with your budget and production goals.

Assess Tolerances, Surface Finishing, and Post-Processing Needs

The final aspect of selecting the right CNC machining techniques involves evaluating tolerances and post-processing needs. Tolerances refer to how much deviation is allowed from the specified dimensions. CNC machining techniques vary in their ability to achieve tight tolerances—grinding, lapping, and honing offer some of the tightest tolerances in the industry, whereas basic CNC milling may be suitable for less critical features. If your project involves extremely tight tolerances, you may need to incorporate multiple CNC machining techniques or secondary finishing processes to meet specifications.

Surface finish is equally important, particularly in applications involving aesthetics, friction reduction, or sealing surfaces. Some techniques naturally produce smoother finishes—such as CNC turning or grinding—while others may require post-processing like polishing, bead blasting, or anodizing. It’s essential to factor in these post-machining processes during the initial planning phase. Choosing CNC machining techniques that align closely with your desired finish can save both time and money while enhancing product performance. Ultimately, a comprehensive approach to machining and finishing will yield components that meet both functional and visual standards.

Conclusion

Choosing the right CNC machining techniques for your project is a strategic decision that significantly influences the final product’s quality, functionality, and cost-effectiveness. By thoroughly evaluating your project’s requirements—from material properties and design complexity to tolerance levels and production volume—you can align your machining process with your goals. A well-informed approach ensures efficient manufacturing workflows, high-precision outcomes, and reduced time-to-market, making your CNC investment worthwhile.

In today’s competitive and highly customized manufacturing landscape, understanding and selecting appropriate CNC machining techniques is not just a technical necessity—it’s a competitive advantage. Collaborate closely with experienced machinists, leverage digital simulation tools, and stay updated with the latest machining technologies to stay ahead. The better you understand your project and available CNC options, the more likely you are to achieve a successful and cost-efficient production outcome.

Comments

0 comment