views

Torquing Tools Market: Innovations, Growth Trends, and Future Prospects

Introduction

In the world of precision engineering and industrial manufacturing, the demand for high-quality torquing tools is rising significantly. From automotive assembly lines to aerospace manufacturing, the importance of accurate torque application cannot be overstated. With the global Torquing Tools Market experiencing steady growth, businesses are investing in advanced torque solutions to enhance efficiency, safety, and productivity.

In this blog, we will explore the market trends, key drivers, challenges, and future prospects of the Torquing Tools Market. Additionally, we will address frequently asked questions and provide insights into how businesses can leverage the latest torquing technology for competitive advantage.

Understanding Torquing Tools and Their Market

What Are Torquing Tools?

Torquing tools are devices designed to apply a specific amount of torque to fasteners such as bolts and nuts. These tools ensure proper tightening, preventing over-tightening or under-tightening, which can lead to equipment failure, safety hazards, or inefficiencies.

Common types of torquing tools include:

🔹 Torque Wrenches – Used for manual and mechanical tightening

🔹 Hydraulic Torque Tools – Ideal for heavy-duty applications

🔹 Pneumatic Torque Wrenches – Powered by compressed air for high-speed operations

🔹 Electronic Torque Tools – Offer digital precision and data recording

Get a free sample to explore the latest insights here:https://www.maximizemarketresearch.com/request-sample/72127/

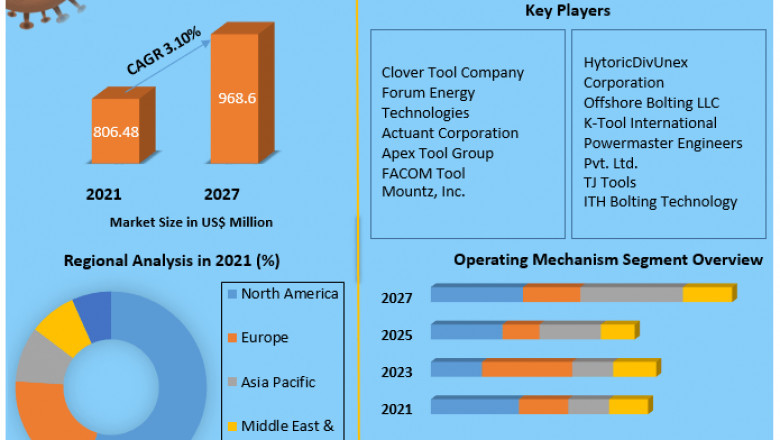

Market Size and Growth Forecast

The Torquing Tools Market is witnessing strong demand due to the expansion of industries such as automotive, construction, aerospace, and oil & gas. Key market insights include:

📌 The global Torquing Tools Market was valued at USD X billion in 2023 and is projected to grow at a CAGR of X% from 2024 to 2030.

📌 Asia-Pacific leads the market, driven by industrialization and infrastructure development.

📌 The automotive sector accounts for a significant market share due to the demand for high-precision torque solutions in vehicle assembly.

Key Market Drivers and Trends

1. Rising Demand for Precision and Efficiency

Industries such as aerospace and defense require highly accurate torque applications to ensure safety and performance. Automated torque tools with real-time monitoring capabilities are gaining popularity.

2. Growth in the Automotive Industry

With the rise of electric vehicles (EVs) and lightweight automotive materials, manufacturers need advanced torquing tools to maintain assembly precision and product durability.

3. Technological Advancements

🔹 Integration of IoT and AI – Smart torque tools provide real-time analytics, remote monitoring, and predictive maintenance.

🔹 Battery-Powered Torque Tools – Cordless torque solutions are becoming popular for their mobility and convenience.

4. Safety and Compliance Regulations

Governments worldwide are enforcing strict safety and quality standards, compelling industries to adopt certified torquing tools for compliance and risk management.

5. Expansion in Renewable Energy Projects

The wind energy sector requires high-torque applications for assembling wind turbine components, driving market growth.

Challenges in the Torquing Tools Market

Despite its growth, the market faces a few challenges:

❌ High Initial Costs – Advanced torque tools, especially those with smart technology, can be expensive for small-scale industries.

❌ Maintenance and Calibration Issues – Regular calibration and maintenance are required to maintain accuracy and compliance.

❌ Skill Gap in Handling Digital Torque Tools – Many industries lack skilled professionals to operate automated and electronic torque tools effectively.

Browse Summary of the Research Report:https://www.maximizemarketresearch.com/market-report/torquing-tools-market/72127/

Frequently Asked Questions (FAQs) About the Torquing Tools Market

1. Why is torque control important in industrial applications?

Proper torque control ensures fastener reliability, prevents structural failures, and enhances operational safety.

2. What are the latest innovations in torquing tools?

The market is shifting toward smart torque tools with wireless connectivity, digital displays, and AI-based monitoring.

3. Which industries rely the most on torquing tools?

🔹 Automotive – Engine assembly and vehicle manufacturing

🔹 Aerospace – Aircraft structural fastening

🔹 Construction – Building steel structures and bridges

🔹 Oil & Gas – Pipeline and refinery maintenance

4. What are the best brands in the torquing tools market?

Leading brands include Snap-on, Ingersoll Rand, Enerpac, Atlas Copco, and Stanley Black & Decker, known for their durability and innovation.

5. How can businesses choose the right torque tool?

Consider application requirements, accuracy levels, torque range, power source (manual, hydraulic, electric), and compliance certifications before purchasing.

Future of the Torquing Tools Market

The torquing tools industry is on a technological transformation, driven by automation, IoT integration, and increased industrial applications. Future trends include:

✔ AI-Powered Torque Monitoring – Enhancing precision with predictive analytics

✔ 3D-Printed Custom Torque Tools – For specialized industrial applications

✔ Eco-Friendly & Energy-Efficient Tools – Battery-operated torque tools reducing carbon footprint

✔ Robotic Torque Applications – Enhancing automation in assembly lines

With growing industrial automation and strict quality control regulations, businesses must invest in next-gen torquing tools to remain competitive.

Conclusion

The Torquing Tools Market is evolving rapidly, fueled by technological advancements, industrial expansion, and safety regulations. Companies investing in precision torque solutions stand to gain from enhanced efficiency, reduced downtime, and improved compliance.

Whether you're in automotive, aerospace, construction, or energy, choosing the right torque tools can transform operational accuracy and productivity. The future belongs to smart, connected, and automated torque solutions, and businesses must adapt to these advancements for sustained growth.

Are you ready to embrace the future of torquing technology? 🚀

Comments

0 comment