views

Pipeline maintenance and integrity assessment are critical for industries that rely on coiled tubing systems. Intelligent pigging is an advanced inspection technique that helps detect internal defects, corrosion, and blockages, ensuring optimal pipeline performance. As industries demand safer and more efficient pipeline operations, adopting intelligent pigging for coiled tubes has become a necessity.

What is Intelligent Pigging?

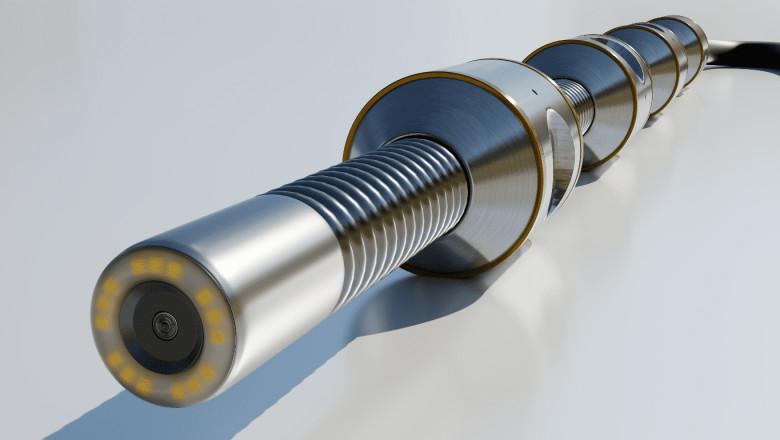

Intelligent pigging is a non-destructive testing (NDT) method that utilizes specialized pipeline inspection devices known as "pigs." These devices travel through the pipeline, collecting data on wall thickness, corrosion levels, and potential defects. Unlike traditional pigging, intelligent pigs are equipped with advanced sensors, enabling detailed diagnostics without disrupting operations.

Why is Intelligent Pigging Essential for Coiled Tubes?

Coiled tubing systems are commonly used in oil and gas, chemical, and industrial applications due to their flexibility and efficiency. However, these pipelines are susceptible to internal wear, corrosion, and debris accumulation. Implementing intelligent pigging for coiled tubes offers multiple advantages:

-

Early Detection of Corrosion: Identifies internal corrosion before it leads to pipeline failure.

-

Blockage Identification: Detects obstructions caused by wax, scale, or debris.

-

Real-Time Data Collection: Provides accurate insights for preventive maintenance.

-

Operational Safety: Reduces the risk of unexpected pipeline failures and costly repairs.

How Does Intelligent Pigging Work?

-

Pig Deployment: The intelligent pig is inserted into the pipeline.

-

Inspection Process: The pig travels through the coiled tube, using ultrasonic, magnetic flux leakage (MFL), or electromagnetic acoustic transducer (EMAT) sensors to collect data.

-

Data Analysis: The collected data is analyzed to detect defects and anomalies.

-

Actionable Insights: Engineers assess the results and recommend necessary maintenance or repairs.

Industries Benefiting from Intelligent Pigging

Several industries rely on intelligent pigging to maintain pipeline integrity:

-

Oil & Gas: Ensures uninterrupted flow and prevents leaks.

-

Chemical Processing: Detects wear in pipelines carrying hazardous materials.

-

Petrochemical: Helps maintain efficiency in high-pressure environments.

Choosing the Right Intelligent Pigging Solution

Selecting a reliable intelligent pigging service is crucial for accurate results. Factors to consider include:

-

Technology Used: Ensure the pigging system includes advanced sensors for high-precision data.

-

Industry Experience: Work with a company that specializes in intelligent pigging for coiled tubes.

-

Regulatory Compliance: Verify adherence to industry standards for pipeline inspection.

Conclusion

With the increasing need for pipeline integrity management, intelligent pigging for coiled tubes has emerged as a game-changing solution. By providing real-time diagnostics and early defect detection, this technology enhances safety, efficiency, and cost-effectiveness across industries. Investing in intelligent pigging solutions is a proactive approach to ensuring uninterrupted operations and regulatory compliance.

Comments

0 comment