views

The Future of Power Distribution: Exploring the Laminated Busbar Market

In today’s fast-paced world, the demand for efficient, compact, and reliable power distribution systems is higher than ever. Enter laminated busbars—a revolutionary solution that is transforming industries ranging from automotive to renewable energy. As the global push for energy efficiency and sustainability gains momentum, the Laminated Busbar Market is experiencing significant growth. But what exactly are laminated busbars, and why are they becoming a cornerstone of modern power distribution systems?

In this blog, we’ll dive deep into the laminated busbar market, exploring its key drivers, applications, benefits, and future trends. Whether you’re an industry professional, a tech enthusiast, or simply curious about the latest advancements in power distribution, this guide has something for you.

Curious about the market dynamics? Get a free sample to explore the latest insights here:https://www.maximizemarketresearch.com/request-sample/818/

What Are Laminated Busbars?

Laminated busbars are advanced electrical components designed to distribute power efficiently within electrical systems. Unlike traditional busbars, which are typically solid metal bars, laminated busbars consist of multiple layers of conductive materials (usually copper or aluminum) separated by thin insulating layers. This unique design offers several advantages, including reduced space requirements, improved thermal management, and enhanced electrical performance.

Key Features of Laminated Busbars

-

Compact Design: Their layered structure allows for a smaller footprint, making them ideal for space-constrained applications.

-

High Efficiency: Reduced impedance and lower inductance result in minimal energy loss.

-

Thermal Management: Improved heat dissipation ensures reliable performance even under high loads.

-

Customizability: They can be tailored to meet specific voltage, current, and space requirements.

Why the Laminated Busbar Market is Booming

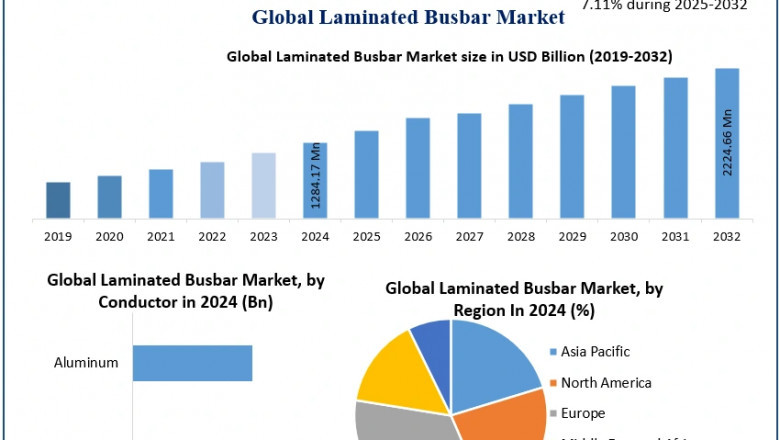

The laminated busbar market is projected to grow at a robust CAGR (Compound Annual Growth Rate) over the next decade. Several factors are driving this growth:

1. Rising Demand for Energy-Efficient Solutions

As industries and governments worldwide prioritize energy efficiency, laminated busbars are becoming a go-to solution for reducing power losses and improving system performance.

2. Growth in Renewable Energy

The renewable energy sector, particularly solar and wind power, relies heavily on laminated busbars for efficient power distribution in inverters and converters.

3. Expansion of the Electric Vehicle (EV) Market

The automotive industry’s shift toward electric vehicles has created a surge in demand for laminated busbars, which are used in battery packs, motor drives, and charging systems.

4. Advancements in Industrial Automation

Modern manufacturing and automation systems require compact, high-performance power distribution solutions, further fueling the laminated busbar market.

To Gain More Insights into the Market Analysis, Browse Summary of the Research Report:https://www.maximizemarketresearch.com/market-report/laminated-busbar-market/818/

Applications of Laminated Busbars

Laminated busbars are versatile components used across a wide range of industries. Here are some of their most common applications:

1. Automotive Industry

-

Electric vehicles (EVs) and hybrid electric vehicles (HEVs)

-

Battery management systems

-

Power inverters and converters

2. Renewable Energy

-

Solar inverters

-

Wind turbine converters

-

Energy storage systems

3. Industrial Machinery

-

Robotics and automation systems

-

Uninterruptible power supplies (UPS)

-

Motor drives and control panels

4. Consumer Electronics

-

Power supplies for laptops, smartphones, and other devices

-

Data centers and server racks

Benefits of Laminated Busbars

The growing adoption of laminated busbars can be attributed to their numerous advantages:

1. Space Savings

Their compact design allows for more efficient use of space, which is particularly valuable in industries like automotive and consumer electronics.

2. Enhanced Performance

Lower inductance and resistance result in reduced energy losses and improved system efficiency.

3. Improved Reliability

Better thermal management and robust construction ensure long-term reliability, even in demanding environments.

4. Cost-Effectiveness

While the initial cost may be higher than traditional busbars, the long-term savings from reduced energy losses and maintenance make them a cost-effective choice.

Key Trends Shaping the Laminated Busbar Market

The laminated busbar market is evolving rapidly, driven by technological advancements and changing industry needs. Here are some of the key trends to watch:

1. Increased Adoption of Copper Laminated Busbars

Copper offers superior conductivity and thermal performance, making it the material of choice for high-performance applications.

2. Integration of Smart Technologies

The incorporation of sensors and monitoring systems into laminated busbars is enabling real-time performance tracking and predictive maintenance.

3. Focus on Sustainability

Manufacturers are increasingly using eco-friendly materials and processes to align with global sustainability goals.

4. Customization and Modular Designs

As applications become more specialized, the demand for customized and modular laminated busbars is on the rise.

Challenges in the Laminated Busbar Market

While the laminated busbar market is thriving, it’s not without its challenges:

1. High Initial Costs

The advanced materials and manufacturing processes involved can make laminated busbars more expensive than traditional alternatives.

2. Complex Manufacturing Processes

Producing laminated busbars requires precision engineering, which can be a barrier for smaller manufacturers.

3. Supply Chain Disruptions

Fluctuations in the availability of raw materials, such as copper, can impact production and pricing.

The Future of the Laminated Busbar Market

The future of the laminated busbar market looks incredibly promising. With the ongoing transition to renewable energy, the rapid growth of the EV industry, and the increasing demand for energy-efficient solutions, laminated busbars are set to play a pivotal role in shaping the future of power distribution.

Key Predictions for the Market

-

Continued growth in the renewable energy and automotive sectors will drive demand.

-

Technological advancements will lead to even more efficient and compact designs.

-

Sustainability will remain a key focus, with manufacturers adopting greener practices.

Conclusion

The laminated busbar market is at the forefront of innovation in power distribution, offering solutions that are not only efficient and reliable but also aligned with the global push for sustainability. As industries continue to evolve, laminated busbars will undoubtedly remain a critical component in meeting the world’s growing energy needs.

Comments

0 comment