views

When it comes to managing pipe penetrations through concrete walls or foundations, a puddle flange is the unsung hero of waterproofing. Whether you are working on a water tank, a sewage plant, or a high-rise basement, puddle flanges play a critical role in preventing leaks and protecting your infrastructure.

In this blog, we’ll explore what a puddle flange is, why it's important, its key types, benefits, and how to choose the right supplier in India.

What is a Puddle Flange?

A puddle flange is a circular steel, PVC, or HDPE ring that is attached to a pipe where it passes through a concrete structure. Its purpose is simple yet vital—it acts as a waterproof barrier to prevent water from leaking along the outer surface of the pipe into the concrete.

It is typically installed during construction and embedded within the concrete. This creates a strong bond that prevents seepage at vulnerable pipe-concrete junctions.

Why Do You Need a Puddle Flange?

Without a puddle flange, moisture and water pressure can gradually seep through pipe entry points. This can lead to:

-

Water damage in underground structures

-

Structural weakening due to corrosion

-

Mold and mildew formation

-

Costly repairs and maintenance

Installing a puddle flange is a preventive solution that ensures water doesn’t find its way into critical areas of your infrastructure.

Where Are Puddle Flanges Used?

Puddle flanges are ideal for environments where waterproofing is essential. They are commonly used in:

-

Basement walls and slabs

-

Sewage and drainage systems

-

Water tanks and reservoirs

-

Lift shafts and pump rooms

-

Underground tunnels and subways

-

Swimming pools

-

Industrial tanks and chimneys

Common Materials for Puddle Flanges

The selection of material depends on the site conditions, type of piping, and the nature of fluids handled.

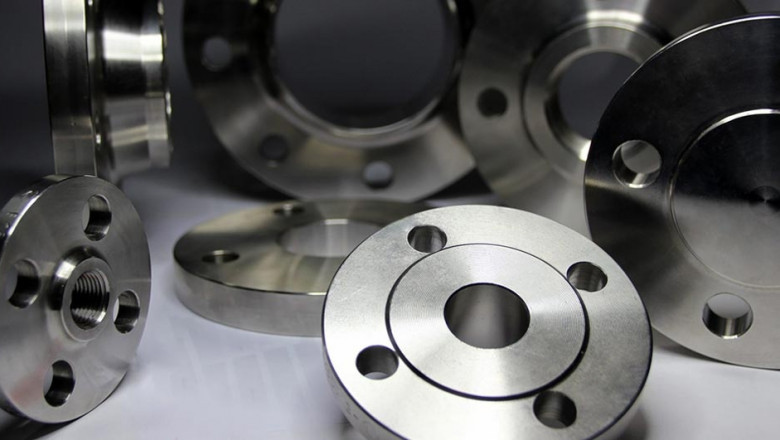

Stainless Steel Puddle Flanges

-

Ideal for corrosive or aggressive environments

-

Common grades: SS 304, SS 316

-

Long-lasting and maintenance-free

Mild Steel Puddle Flanges

-

Used in less corrosive environments

-

Usually coated for rust protection

-

Cost-effective for large projects

PVC / HDPE Puddle Flanges

-

Lightweight and easy to install

-

Suitable for plastic piping systems

-

Chemical and moisture-resistant

Types of Puddle Flanges

Welded Puddle Flanges

-

Welded directly to the pipe

-

Provides a permanent and secure seal

Split Puddle Flanges

-

Two-piece design

-

Ideal for retrofitting around already-installed pipes

Rubber-Coated Flanges

-

Includes an elastomer coating

-

Ensures tight sealing and flexibility

Key Benefits of Puddle Flanges

1. Excellent Waterproofing

Puddle flanges prevent leakage at the joint between pipes and concrete, reducing risk of water damage.

2. Structural Protection

By blocking water ingress, they protect the concrete from corrosion, spalling, and mold.

3. Versatility

Compatible with metal, plastic, and concrete pipes across multiple industries.

4. Long-Term Performance

Made from high-quality corrosion-resistant materials, they last as long as your structure does.

5. Low Maintenance

Once installed correctly, puddle flanges rarely need repair or replacement.

How to Install a Puddle Flange

Proper installation is crucial for the effectiveness of the flange. Here's how it works:

🔧 Step 1: Fit the Flange to the Pipe

Position the puddle flange at the correct location on the pipe where it will be cast into concrete.

🔧 Step 2: Secure the Flange

Use welding, clamps, or adhesive depending on the material to secure the flange to the pipe.

🔧 Step 3: Embed in Concrete

The pipe with the flange is set in place and concrete is poured around it to form a waterproof seal.

🔧 Step 4: Final Inspection

Check alignment and integrity after curing to ensure no gaps are present.

Tips for Selecting the Right Puddle Flange Supplier

When choosing a puddle flange supplier in India, here’s what to look for:

-

Material variety: Stainless steel, MS, PVC, HDPE

-

Customization: Sizes, coating, and flange types

-

Certifications: ISO, ASTM, and quality standards

-

Logistics support: Timely delivery and packaging

-

Technical assistance: For installation and product selection

Why Choose a Puddle Flange Supplier in India?

India is a hub for manufacturing high-quality engineering products, including puddle flanges. Indian suppliers are known for:

-

Competitive pricing

-

Wide material availability

-

Custom manufacturing capabilities

-

International exports to UAE, Europe, Africa, and more

You’ll find several reputed puddle flange exporters in India who supply to construction companies, municipal contractors, and industrial plants globally.

Conclusion

A puddle flange may seem like a small component, but its role in waterproofing is critical. It forms a reliable seal that keeps structures dry, safe, and corrosion-free. Whether for a commercial basement or a large sewage plant, puddle flanges ensure long-lasting protection against water ingress.

Comments

0 comment