views

In the world of construction and DIY projects, ensuring accuracy and precision is essential for achieving professional-level results. Whether you’re a seasoned contractor or an enthusiastic DIYer, one tool that has revolutionized the way we measure and level surfaces is the laser level. But how exactly does it ensure precision, and why has it become an indispensable tool on job sites? In this article, we’ll explore the various ways a laser level works to enhance accuracy in construction projects.

Understanding the Laser Level

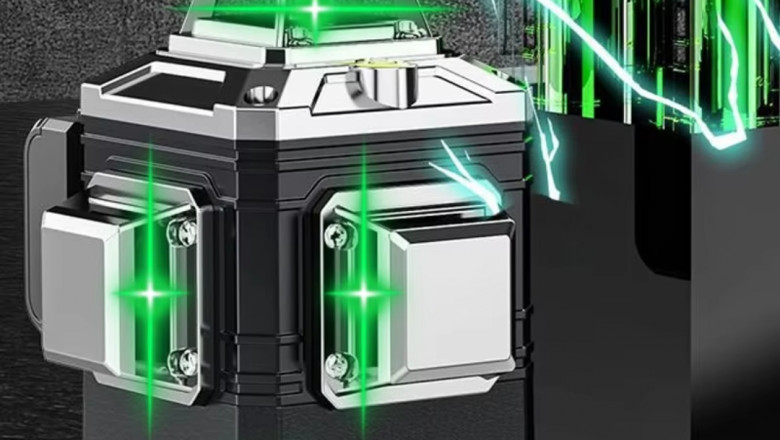

Before diving into the details of how a laser level ensures precision, it’s important to understand what this tool is and how it operates. A laser level is a device that projects a laser beam onto a surface to create a perfectly level line or point. These devices use the principle of light to ensure that the beam remains level, providing users with an easy way to establish reference points in both horizontal and vertical directions.

Laser levels come in a variety of models, each suited to different types of projects. Some provide a single line, while others offer cross-line lasers or even 360-degree coverage. Regardless of the type, all laser levels are designed to ensure that the laser beam remains accurate and level across a wide range of distances and surfaces.

Ensuring Precision in Measurements

Precision is the cornerstone of any successful construction project, whether it’s hanging pictures, installing cabinets, or laying the foundation for a building. When it comes to leveling surfaces, a small error can lead to significant issues down the line. A laser level takes the guesswork out of the equation by providing a highly accurate reference point.

Unlike traditional methods, such as using a bubble level or measuring tape, a laser level gives a straight, visible line or dot that can be easily aligned. The laser beam can project across large distances without distortion, ensuring that your reference line stays true, even if you’re working in large or complex spaces. This means that a laser level can maintain its precision over much longer distances than a traditional level, ensuring that measurements stay consistent and reliable.

Versatility in Application

One of the most significant advantages of using a laser level in construction is its versatility. A laser level is not confined to just one application but can be used in a variety of ways. Whether you're working on flooring, tiling, drywall, framing, or even landscaping, a laser level ensures that you achieve a high degree of precision in all these tasks.

For example, when installing tile flooring, a laser level can project a perfectly straight line across the entire room, ensuring that the tiles are aligned consistently. In framing, a laser level can help ensure that studs are installed in perfect alignment, which is critical to the overall integrity of the structure.

Furthermore, the ability to project both horizontal and vertical lines allows users to work in both directions simultaneously. This is especially useful when hanging cabinets or installing shelves, as you can align the laser level with both the floor and the ceiling to ensure that the installation is perfectly straight.

Laser Level and the Human Eye

While traditional levels and measuring tools rely on the human eye to judge whether something is straight, a laser level removes that subjectivity. The laser beam is a constant reference point that doesn’t waver or fluctuate, eliminating any potential for error caused by misjudgment. This is particularly helpful in large-scale projects, where minor inaccuracies can lead to big problems down the line.

The brightness and visibility of the laser beam also contribute to the precision of the tool. In dimly lit environments or areas with lots of distractions, a laser level can still maintain its clarity and accuracy, ensuring that your measurements are never compromised. Some models even come with features like self-leveling, which automatically adjusts the laser to ensure that it’s perfectly aligned, further increasing the tool's accuracy.

How Laser Levels Enhance Workflow

Another way a laser level contributes to precision is by speeding up the workflow. In construction, time is often as valuable as accuracy. Traditional leveling methods can be time-consuming and labor-intensive. Using a laser level, however, simplifies the process. The visible laser line can quickly be aligned with your desired reference point, significantly reducing the time spent on measurements and adjustments.

Moreover, since laser levels offer real-time visual feedback, it’s much easier to make adjustments on the fly. This allows construction professionals to make quick decisions and modifications without having to start over or recheck measurements multiple times.

Laser Level Calibration and Accuracy

For a laser level to maintain its high level of precision, it must be calibrated correctly. Calibration ensures that the laser beam remains true, and any small misalignments can be corrected before they become larger issues. Many laser levels feature self-calibration systems that automatically adjust the beam to maintain accuracy.

This feature is particularly important in environments where the level of precision required is extremely high. For example, in large-scale construction projects or when installing expensive materials, it’s crucial that each measurement is perfect. A laser level can help prevent mistakes and inaccuracies by ensuring that the beam remains consistently aligned.

Overcoming Environmental Challenges

Environmental factors can also impact the accuracy of traditional leveling methods. For example, uneven flooring or surfaces can throw off the calibration of a bubble level, leading to inaccuracies. Similarly, working in spaces with poor lighting or obstructed lines of sight can make it difficult to accurately judge measurements.

A laser level, on the other hand, can overcome many of these challenges. Since the laser beam is visible and easily projected across surfaces, it remains unaffected by uneven floors or low lighting. Additionally, modern laser levels are designed to work in a variety of conditions, with many models offering features like dust resistance, water resistance, and even the ability to function in outdoor environments.

The Role of Laser Levels in Safety

Precision is not only about achieving the desired results—it’s also about maintaining safety. Incorrectly aligned structures can lead to accidents, which is why using a laser level to ensure accuracy is essential. Whether you're leveling a foundation or installing heavy equipment, ensuring everything is correctly aligned can prevent costly and dangerous mistakes. The laser level provides a clear, visible reference point that ensures each element is positioned correctly, thus enhancing safety on the job site.

Final Thoughts

In the realm of construction, precision is more than just a luxury—it’s a necessity. A laser level ensures that your measurements remain true, providing a consistent reference point across various projects and environments. Whether you’re working on a large commercial building or a smaller DIY project, a laser level allows you to achieve accuracy quickly and efficiently. The versatility, ease of use, and precision it offers make it a must-have tool for any construction professional or DIY enthusiast.

Comments

0 comment