views

Vortex’s Guide to Selecting Mixer Construction Materials - VORTEX Mixing Technology

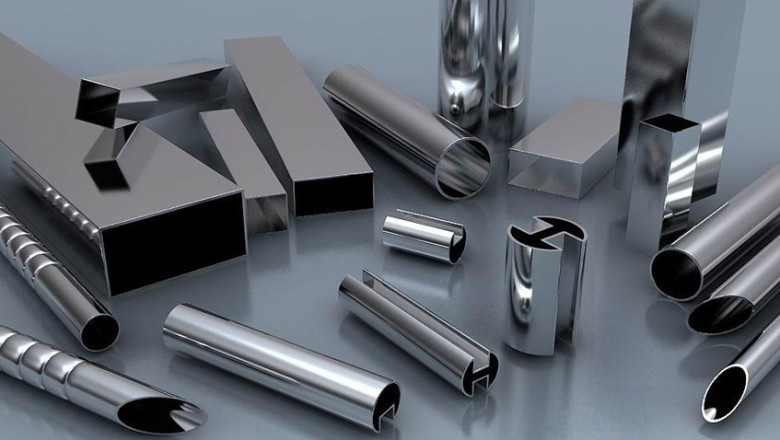

In the field of industrial mixing, the selection of construction material is pivotal. It influences not only the durability and performance of the mixer but also its compliance with industry-specific standards. Whether you’re in the food processing, pharmaceutical, chemical, or heavy machinery sector, understanding the properties of various materials can guide you to make informed decisions. Now, Vortex Mixing Technology‘ guide will delves into three commonly used materials: 304 stainless steel, 316 stainless steel, and carbon steel, highlighting their characteristics, applications, and considerations.

Composition: Approximately 18% chromium and 8% nickel (commonly referred to as 18/8 stainless steel).

Key Properties:

Standards Compliance: Must adhere to GB/T 20878-2007, which specifies a maximum carbon content of 0.08% and strict limits on heavy metal content.

Applications: Widely used in kitchenware, tableware, and food processing equipment due to its hygienic properties.

Considerations: It’s important to note that not all 304 stainless steel is food-grade. Food-grade 304 requires national standard certification to ensure lower levels of harmful elements such as lead and cadmium.

Composition: Contains 16–18% chromium, 10–14% nickel, and 2–3% molybdenum.

Key Properties:

Superior Corrosion Resistance: The addition of molybdenum enhances resistance to chlorides and acids, making it ideal for marine and chemical environments.

Durability: Offers excellent strength and durability, even in high-salt or high-chlorine conditions.

Applications: Commonly used in high-end kitchenware, medical equipment, and marine food processing equipment.

Considerations: While more expensive than 304 stainless steel, 316’s enhanced properties make it a preferred choice for applications requiring higher corrosion resistance.

Composition: An iron-carbon alloy with carbon content ranging from 0.0218% to 2.11%. Also contains small amounts of silicon, manganese, sulfur, and phosphorus.

Key Properties:

Strength and Hardness: Higher carbon content increases hardness and strength.

Cost-Effective: Generally less expensive than stainless steels, making it suitable for budget-conscious projects.

Applications: Used in heavy machinery, structural components, and applications where high strength is required.

Considerations: Higher carbon content reduces plasticity and weldability. Additionally, carbon steel is more susceptible to corrosion and may require protective coatings or treatments.

Selecting the appropriate construction material for your mixer is a critical decision that impacts performance, longevity, and compliance with industry standards. By understanding the distinct properties and applications of 304 stainless steel, 316 stainless steel, and carbon steel, you can make informed choices that align with your operational needs and environmental conditions. Always ensure that the materials meet the necessary certifications and standards pertinent to your industry to guarantee safety and efficiency.

If you need help determining the construction materials—or want to improve your mixing efficiency—don’t hesitate to contact us. Our equipment is engineered to deliver the precision and repeatability your process deserves.

Hot Search:Mixers

Conical Screw Mixer(Nauta Mixer)

Ribbon Blender Mixer

Twin Shaft Paddle Mixer

Vertical Ribbon Mixer

Copyright © 2017- 2025 VORTEX Mixing Technology All Rights Reserved

Comments

0 comment