views

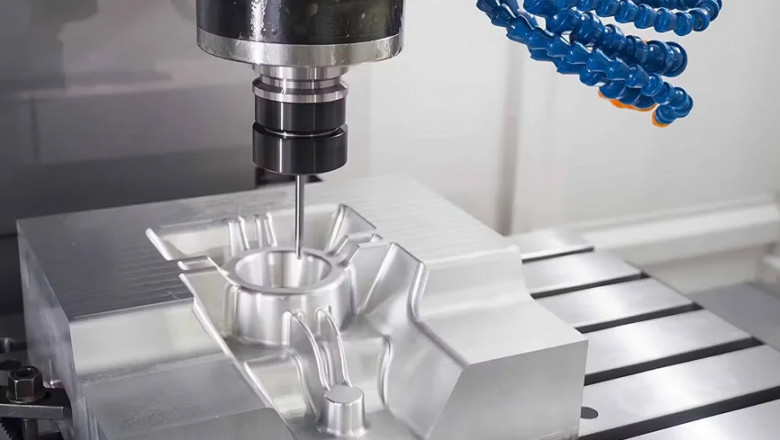

CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, offering unmatched precision, repeatability, and efficiency. It is widely used across various sectors, helping industries produce complex parts with high accuracy. From aerospace to medical devices, CNC machining plays a critical role in supporting quality and innovation in production processes.

Aerospace Industry

The aerospace industry is one of the largest users of CNC machining due to its demand for highly precise and reliable components. To understand its importance, it's essential to know what is CNC machining—a computer-controlled manufacturing process that allows for the production of complex and accurate parts. Aircraft parts must meet stringent safety and quality standards, and CNC machines produce critical elements such as turbine blades, engine mounts, structural frames, and interior components with extremely tight tolerances. The ability to machine complex geometries and lightweight materials like aluminum and titanium makes CNC machining essential in aerospace manufacturing.

Automotive Industry

CNC machining is heavily relied upon in the automotive sector for producing both prototype and production parts. Components such as engine blocks, gearboxes, brake systems, and custom interior elements are commonly made using CNC processes. It ensures consistency and speed in mass production while supporting the development of performance-enhancing and safety-critical parts. CNC machining is also used in creating molds and dies for large-scale vehicle production.

Medical Industry

The medical field demands ultra-precise components that meet strict hygiene and safety standards. CNC machining is used to create surgical tools, orthopedic implants, dental devices, and prosthetic parts. These products often require custom configurations and biocompatible materials like titanium and stainless steel. The high precision of CNC machining ensures the safety, reliability, and effectiveness of medical devices used in treatment and diagnosis.

Electronics Industry

In electronics, CNC machining is used to manufacture enclosures, connectors, heat sinks, and small metal or plastic components for devices like smartphones, computers, and industrial systems. As electronic products shrink in size, CNC machining supports the need for tiny, complex parts with excellent surface finishes. It also plays a role in producing prototypes and testing assemblies during the product development stage.

Defense and Military

Defense applications require durable and high-performance components for equipment such as weapons, vehicles, and communication systems. CNC machining helps produce parts with exacting specifications, often from high-strength materials that can withstand extreme conditions. The repeatability and precision of CNC processes make them ideal for defense projects where reliability is critical.

Industrial Equipment and Tooling

Manufacturers of heavy equipment and industrial tools also depend on CNC machining. It is used to produce machine parts, gears, shafts, and custom tools for a wide range of applications. CNC ensures accuracy and durability, which are essential for equipment that must operate under high stress and for long durations.

Conclusion

CNC machining is a vital technology across many industries, thanks to its ability to deliver precision, consistency, and speed in manufacturing. Aerospace, automotive, medical, electronics, defense, and industrial sectors all rely heavily on CNC machining to meet their production and quality standards. As product complexity increases and tolerances become tighter, the demand for CNC machining will continue to grow, reinforcing its role as a foundational process in modern industry.

Comments

0 comment