views

Plastic injection molding remains a cornerstone of modern manufacturing, enabling the production of complex, durable plastic parts at scale. In 2025, advancements in technology and increased demand for customization are reshaping how businesses choose their plastic injection molding partners. Whether you're an entrepreneur launching a new product or a seasoned manufacturer optimizing your production line, selecting the right plastic injection molding services can make all the difference in cost, efficiency, and product quality.

This expert guide explores what to look for in the best plastic injection molding services in 2025, delving into key considerations such as technological capabilities, industry certifications, customer service, pricing models, and sustainability. Read on to discover how to navigate the evolving landscape of injection molding and choose a partner that fits your production goals.

Understanding Plastic Injection Molding Services in 2025

Plastic injection molding services involve creating plastic components by injecting molten plastic into a custom mold. In 2025, these services are no longer limited to simple plastic parts; they cater to a wide array of industries including automotive, healthcare, electronics, consumer goods, and aerospace. Enhanced by automation, robotics, and AI-driven design optimization, modern injection molding now offers precision, repeatability, and rapid turnaround times at competitive prices.

The best plastic injection molding services in 2025 go beyond basic production—they offer design assistance, material selection guidance, and value-added services like secondary assembly and post-processing. As supply chain resilience becomes critical, top service providers are also investing in localized production and real-time inventory management tools. Understanding the full scope of these offerings is the first step in identifying the right partner for your needs.

Key Technologies Revolutionizing Plastic Injection Molding

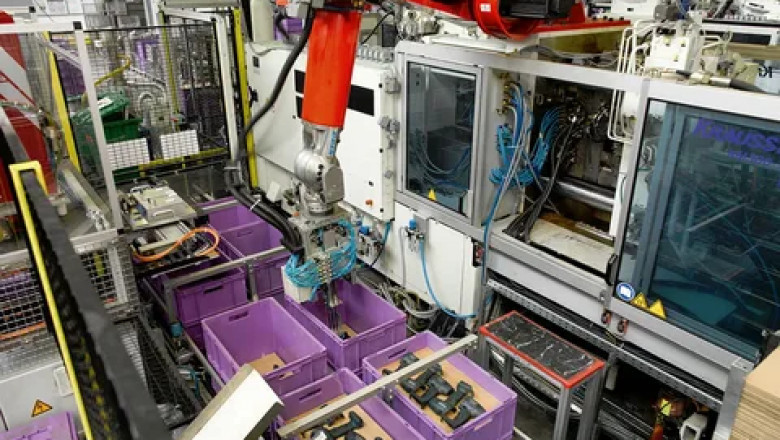

Technological innovation is transforming plastic injection molding services in 2025. Companies are leveraging Industry 4.0 tools such as IoT-enabled machines, real-time monitoring systems, and cloud-based production data tracking. This integration of smart technologies ensures better quality control, predictive maintenance, and overall production efficiency. Advanced simulation software also allows for virtual mold testing, reducing costly errors and accelerating the product development timeline.

Another game-changer is the emergence of hybrid molding solutions that combine traditional methods with additive manufacturing techniques. This approach enables rapid prototyping, mold revisions, and small-batch customization. In addition, robotic automation and AI-driven inspection tools enhance precision, minimize defects, and reduce labor costs. When evaluating plastic injection molding services, it’s essential to assess the provider’s technological capabilities and willingness to invest in innovation.

What to Look for When Choosing a Molding Service Provider

Selecting a plastic injection molding service in 2025 involves more than comparing quotes—it requires a strategic evaluation of a provider’s experience, certifications, capabilities, and customer support. First, ensure the company has a proven track record in your industry. Check for ISO certifications like ISO 9001 or IATF 16949 (automotive), which guarantee quality management systems. Ask for client testimonials and review case studies that highlight successful projects similar to yours.

Also consider the range of services offered, from prototype development and mold design to high-volume production and packaging. Some providers specialize in rapid tooling or overmolding, while others focus on complex geometries or tight tolerances. It's crucial to find a service that aligns with your technical requirements and project scope. In 2025, top-tier plastic injection molding services act as strategic partners, not just manufacturers, guiding clients through every stage of the product lifecycle.

Cost Factors and Customization Options in 2025

Cost-efficiency continues to be a driving factor when choosing plastic injection molding services, but in 2025, it’s all about balancing price with value. Upfront tooling costs remain a significant investment, but many providers now offer cost-saving models like mold-sharing, modular tooling, or low-volume production packages. These options can dramatically reduce initial expenses while still offering scalable production capabilities.

Customization has also taken center stage, with many manufacturers offering a broader range of thermoplastic materials, color matching, surface finishes, and design flexibility. Advanced computer-aided engineering (CAE) and simulation tools allow for optimization of part design before the first mold is even created, saving both time and money. When evaluating costs, consider not only the price per unit but also the long-term benefits of a partner who offers flexibility, quality assurance, and production scalability.

Sustainability and Eco-Friendly Practices in Modern Molding

As environmental regulations tighten and consumers demand more sustainable products, the best plastic injection molding services in 2025 are embracing eco-friendly practices. These include using biodegradable or recycled plastics, energy-efficient molding machines, and closed-loop production systems. Some providers also participate in take-back programs or offer biodegradable packaging solutions, helping brands meet their environmental goals.

Another trend is the shift toward local sourcing and shorter supply chains, which reduces transportation emissions and improves response times. Digitalization is also contributing to sustainability by minimizing waste through virtual mold simulations and efficient scheduling. When choosing a service provider, ask about their sustainability certifications, green initiatives, and how they manage scrap material. Partnering with an environmentally responsible injection molding service is not only good for the planet—it’s also a smart business decision in a climate-conscious market.

Conclusion

The landscape of plastic injection molding services in 2025 is dynamic, tech-driven, and customer-focused. As industries evolve and demands become more complex, partnering with the right service provider is crucial for achieving quality, speed, and cost-effectiveness. By understanding the technological advancements, evaluating key service features, comparing pricing models, and prioritizing sustainability, businesses can make informed decisions that position them for long-term success.

Whether you're launching a startup or managing a global supply chain, the best plastic injection molding services offer more than manufacturing—they provide innovation, collaboration, and strategic insight. Use this expert guide as your roadmap to navigate the options and choose a partner that will help bring your product vision to life in 2025 and beyond.

Comments

0 comment