views

Twin Shaft Paddle Mixer’s Application in Chemistry - VORTEX Mixing Technology

In the field of industrial chemistry, precision, consistency, and efficiency are crucial to ensuring high-quality product outcomes and scalable operations.

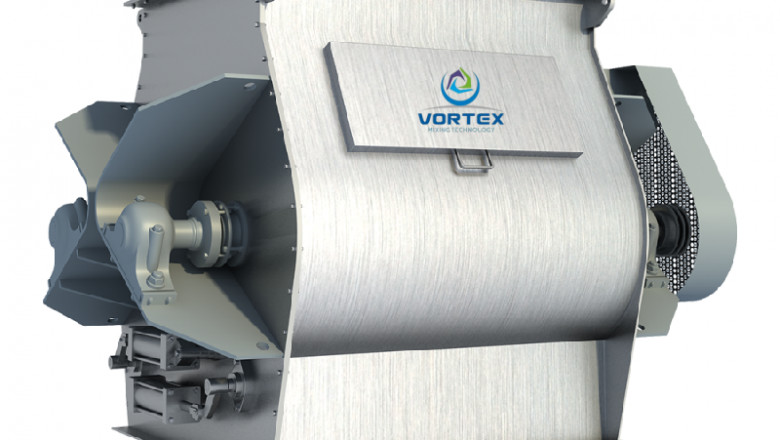

Among the array of processing equipment employed in chemical plants and laboratories, the twin shaft paddle mixer stands out for its exceptional mixing capabilities, particularly when dealing with complex, heterogeneous materials. This article explores the design, function, and specific applications of twin shaft paddle mixers in the chemical industry.

A twin shaft paddle mixer is an industrial mixing device equipped with two horizontal shafts mounted with paddles that rotate in opposite directions. These paddles are designed to lift and tumble materials in a gentle yet thorough motion, achieving high levels of homogeneity in the mix. The equipment is especially suitable for mixing powders, granules, pastes, and even certain liquids, depending on the application.

In industrial chemistry, the precise blending of solid particles is fundamental to ensuring uniform product characteristics. This is particularly important in the formulation of catalysts, pigments, fertilizers, and specialty chemicals, where even minor variations can lead to performance issues.

Twin shaft paddle mixers excel in dry blending by creating a fluidized zone where materials are suspended momentarily, allowing particles of varying sizes and densities to mix thoroughly.

Their ability to prevent segregation, reduce clumping, and eliminate dead zones ensures high-quality, repeatable results. These attributes are especially valuable in powder metallurgy and ceramic processing where consistency is critical.

Integrating liquid components into solid matrices is a common requirement in the production of detergents, adhesives, rubber compounds, and polymer composites. Twin shaft paddle mixers allow controlled addition of liquids via integrated spray nozzles or injectors, ensuring even distribution without overwetting or under-mixing.

The dynamic paddling action allows for the quick dispersion of liquids, transforming dry powders into homogeneous slurries, pastes, or wet granules. This function is also widely used in the preparation of resin blends, textile finishing agents, and cosmetic intermediates.

In processes like microencapsulation, controlled-release formulations, dust control, and agglomeration, achieving a uniform coating of particles with active ingredients, binders, or waxes is essential. Twin shaft paddle mixers create a mechanically fluidized environment that facilitates even coating of every particle.

The system is capable of handling fine powders without generating excessive dust, making it suitable for producing non-dusting powders or granular chemical products with improved flowability and handling characteristics. Additionally, binders and liquid agents can be sprayed into the mix to create layered granules or composite particles.

Some chemical compounds are prone to degradation, volatilization, or reaction acceleration when exposed to excessive heat. The low-shear, gentle mixing action of twin shaft paddle mixers minimizes friction and associated heat buildup, making them ideal for thermally sensitive applications.

This is especially beneficial in the production of peroxides, initiators, enzymes, or bio-based chemicals, where maintaining chemical stability is paramount. Additionally, paddle mixers can be fitted with jacketed vessels for controlled heating or cooling, further enhancing temperature management.

Before undergoing chemical reactions in reactors or downstream processing units, reactants often need to be pre-mixed to ensure uniformity and optimize reaction kinetics. Twin shaft paddle mixers are ideal for this preparatory stage, producing homogeneous, well-dispersed mixtures of solids and/or liquids that enhance the efficiency and predictability of chemical reactions. This step is crucial in the production of polymers, pharmaceutical actives, and intermediates, where consistency directly affects yield and product quality.

In processes such as water treatment, waste neutralization, or soil remediation, paddle mixers are used to incorporate alkalis, acids, or conditioning agents into bulk solids or slurries. Their rapid mixing ensures fast and even distribution of pH-adjusting chemicals, preventing localized over-concentration. This capability is essential for creating safe, stable, and effective chemical blends used in environmental applications.

In the production of colored masterbatches, pigment dispersions, and dye-based formulations, uniform color distribution is essential. Twin shaft paddle mixers achieve this by providing thorough dispersion without particle degradation, preserving the optical and physical properties of the colorants. This is crucial in industries such as textiles, plastics, and inks.

The twin shaft paddle mixer has become an essential asset in modern chemical processing, offering a unique combination of efficiency, versatility, and control. Its ability to handle a wide range of materials—whether powders, pastes, or granules—makes it indispensable across various stages of chemical manufacturing, from initial blending to final product conditioning.

With advantages such as gentle yet effective mixing, scalability, and compatibility with heat-sensitive or reactive materials, this mixer supports consistent product quality and streamlined operations. As the chemical industry continues to evolve toward more complex formulations and tighter quality standards, the twin shaft paddle mixer stands out as a reliable solution for both innovation and production excellence.

Hot Search:Mixers

Plough Shear Mixer

Ribbon Blender Mixer

Twin Shaft Paddle Mixer

Conical Screw Mixer(Nauta Mixer)

Copyright © 2017- 2025 VORTEX Mixing Technology All Rights Reserved SiteMap

Comments

0 comment